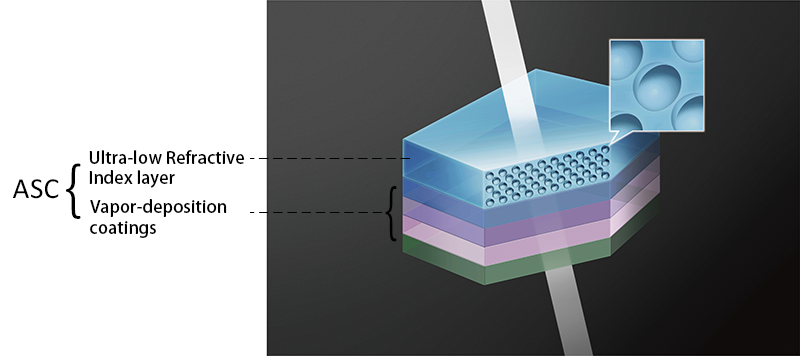

In November 2014, Canon announced the EF 100-400mm f/4.5-5.6L IS II USM super telephoto zoom lens, the first Canon EF lens to incorporate the newly developed Air Sphere Coating (ASC) technology. Air Sphere Coating is an anti-reflection technology that combines the existing vapor-deposited multi-layer coatings with an ultra-low refractive index outermost layer, which comes in contact with air. ASC significantly reduces flare and ghosting that cannot be prevented with conventional vapor-deposited multi-layer coatings, improving anti-reflection performance.

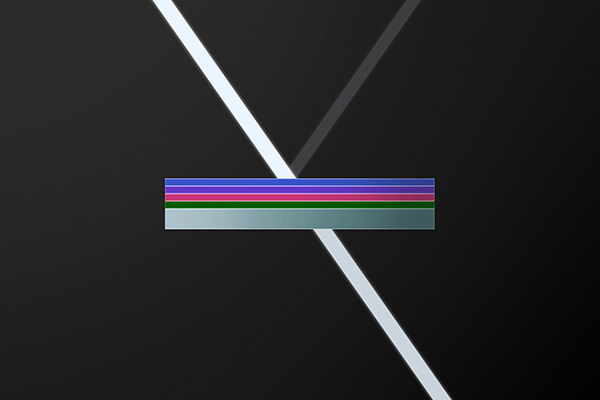

ASC Structure (Cross-section)

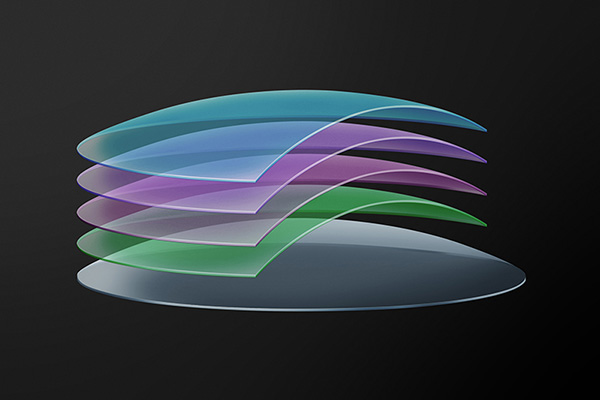

Multi-layer Coating: Super Spectra Coating

When light enters or exits an uncoated lens approximately 5% of the light is reflected back at each lens-air boundary due to the difference in refractive index. This reflected light causes flare and ghosting, which results in deterioration of image quality. To counter this, a vapor-deposited coating that reduces light reflection is applied to the lens surface. The anti-reflective vapor-deposited coating process is called Super Spectra Coating within Canon.

Super Spectra Coating is made up of a number of thin films with the correct refractive index differences (i.e., multi-layer coating), which cancels out reflections by using the destructive interference between reflected light at each of the boundaries between the vapor-deposited films. This allows high levels of anti-reflectance (low reflectance) to be achieved across a wide range of wavelengths. This combination of layers is organized so that the outermost layer (which comes into contact with the air) has a low refractive index that is closer to that of the air. This is known to yield higher levels of anti-reflectance. Apart from anti-reflection, Super Spectra Coating also unifies the color balance of multiple lenses used in EF lenses, maintaining a high level of color consistence among all EF Lens models.

Super Spectra Coating is made up of multiple layers of coating

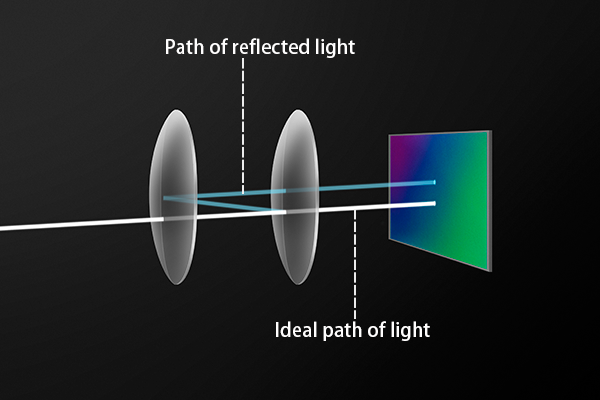

Flare and ghosting

Multi-layer anti reflection coating is most effective when incident light is vertical to the lens; the anti-reflection effect diminishes with increasing angle of incident. Flare and ghosting thus cannot be prevented in certain situation. Ghosting and flare are the result of light reflected off a lens surface hitting the sensor and other lenses and showing up in the image. Flare is indicated by part of the images turns white due to a strong light such as backlight, where ghosting is an accumulation of light occurs when it should not be there.

Cause of flare and ghosting

Example of ghosting

Example of flare

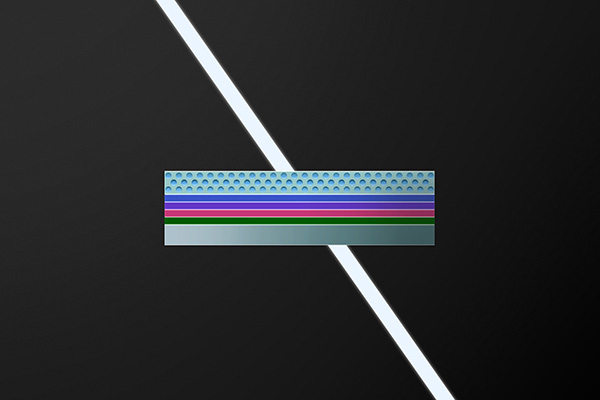

Air Sphere Coating (ASC)

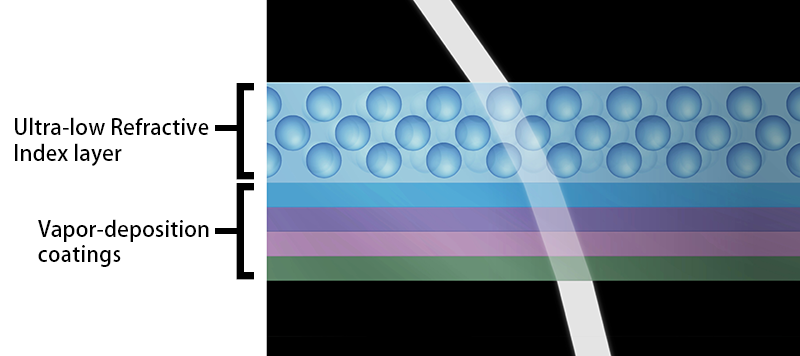

To further reduce flare and ghosting resulted from reflection, Canon has developed the Air Sphere Coating technology. As mentioned above, ASC is a combination of the existing vapor-deposited multi-layer coatings with an ultra-low refractive index outermost layer. The ultra-low refractive index outermost layer is a film that includes microscopic nano-sized air spheres arranged in regular structure. The resulting structural refractive index provides an ultra-low refractive index significantly lower than that of the existing vapor-deposited coatings. Although there is air inside the ultra-low refractive index layer, the air spheres have a diameter of 10 nm (nanometers), which are microscopic when comparing to the wavelength of visible light and as they are in an ordered array, light does not scatter. With the ultra-low refractive index layer, ASC achieves far lower reflectance and significantly reduces flare and ghosting that cannot be prevented with conventional vapor-deposited multi-layer coatings.

ASC Structure (Cross-section)

Anti-reflection effect comparison

(Left: ASC Right: Existing Multi-layer Coating)

Reflectivity of coatings

(no coating)

A highly reflective glass surface only. Almost all light that enters is reflected.

(vapor-deposition coatings)

Even the multi-layer coating with a higher transmission factor reflects some of the incident light.

By using ASC, reflected light is reduced, making it possible to accurately bring in more light.

ASC and SWC

ASC utilizes the anti-reflection principle from destructive interference of light, and it has excellent anti-reflective effects particularly with respect to incident light that enters almost vertically. However, even with increased angle of incidence, ASC still can significantly reduces flare and ghosting that cannot be prevented with conventional vapor-deposited multi-layer coatings. ASC can also be applied to a variety of lenses, making it extremely versatile.

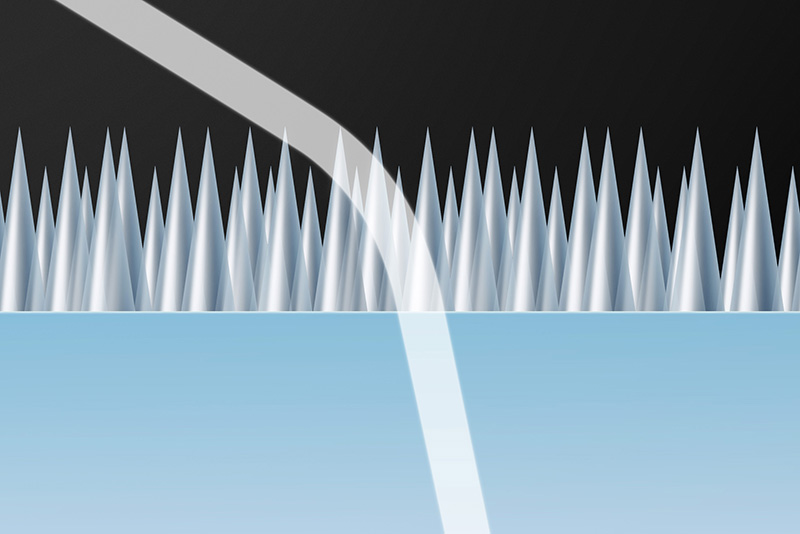

The Subwavelength Structure Coating (SWC), on the other hand, applies a different anti-reflective principle. The advanced Canon developed technology uses a special process to arrange a countless number of nano-scaled (200-400nm) pyramidal structures, smaller than the wave length of visible light, on the lens surface. Since there are no surface boundaries where refraction indices change significantly, making it possible to prevent the reflection of light by implementing gradual refractive index modifications between air and lens. SWC has excellent angle of incidence characteristics, exhibiting excellent anti-reflective effects even for light with particularly large angles of incidence, even better than ASC. As SWC can also applied to surfaces with significant curvature, it is now possible to reduce ghosting and flare that can occur around the periphery of even lens elements with a large curvature in wide angle lenses.

The nano-scaled pyramidal structures of SWC

Lens Design and Coating

From the initial design stage of a lens’ optical design, the importance of reducing flaring and ghosting has already been taken into consideration. Base on the lens types and specifications, Canon engineers utilize SWC or ASC on the most appropriate lens surface to reduce flare and ghosting in order to raise image quality. This is same as the utilization of fluorite, UD glass, ground aspherical lens or glass-molded aspherical lens, consideration is made for the total performance by using the right element in the right place.